Professional, Portable Meat pH Meter - HI98163

- Quick Connect DIn Connector

- USB Connection for Data Transfer

- Dedicated Help Button

In the meat processing industry, the monitoring of pH is considered to be of the utmost importance due to its effect on the meat's quality factors including water binding capacity and shelf life. Upon slaughter, biochemical processes begin to break down the meat. Glycolysis begins post-mortem, converting glycogen to lactic acid, reducing the pH of the carcass. Depending on a number of factors such as type of animal and even breed, this decrease in pH can take anywhere from a single hour to many. It is vital to monitor pH during this phase as once the lowest pH value is reached, the pH will begin to slowly rise, indicating that decomposition has begun.

The pH value of meat influences its’ water binding capacity which directly impacts consumer qualities such as tenderness and color. Lower pH values result in a lower water-binding capacity and lighter colors. Factors such as these can be important when considering how to efficiently produce meat products. For example, when producing dry sausages the meat must have a low water binding capacity so that it can dry evenly.

Depending on the type of the final product and the steps required to get there, pH values will vary throughout the meat processing industry. It is imperative, regardless of the final product, that pH be maintained at a low value to prevent bacterial spoilage and comply with food safety regulations. By monitoring pH values throughout the meat production process, you can ensure the creation of consistent and safe meat products.

Meat products can provide a number of challenges for the person that needs to measure pH. Oils and solids from the meat can coat the sensitive glass membrane surface and/or clog the reference junction. The FC2323 that is supplied with the HI98163 is designed specifically for measuring pH in meat. Design considerations include a stainless steel piercing blade around conic tip shape probe for easy penetration, an open junction that resist clogging, and a Polyvinylidene Fluoride (PVDF) food grade plastic body that is resistant to most chemicals and solvents, including sodium hypochlorite. It has high abrasion resistance, mechanical strength and resistance to ultraviolet and nuclear radiation. PVDF is also resistant to fungal growth. The FC2323 is an ideal general-purpose pH electrode for meat that connects to the HI98163 with a quick-connect, waterproof DIN connector, allowing for a secure, non-threaded attachment.

The FC2323 is an amplified pH electrode with a built-in temperature sensor. This probe is designed with low temperature (LT) glass, a conical tip shape, and is housed in a food grade PVDF body with a removable, piercing stainless steel blade. This electrode also features a unique open junction design in which there a viscolene (hard gel) electrolyte layer that is free of silver chloride (AgCl) between the sample to be measured and the internal reference cell. The open junction design resists clogging and the probe’s conical tip makes it ideal for pH measurements in meat and semi-solid food samples.

Conical Glass Tip

The conical shaped tip design allows for penetration into solids, semi-solids, and emulsions for the direct measurement of pH in food products including meat, cheese, yogurt, and milk.

Open Junction Reference

The open junction design consists of a solid gel interface (viscolene) between the sample and internal Ag/AgCl reference. This interface not only prevents silver from entering the sample, but also makes it impermeable to clogging, resulting in a fast response and stable reading.

PVDF Body

Polyvinylidene fluoride (PVDF) is a food grade plastic that is resistant to most chemicals and solvents, including sodium hypochlorite. It has high abrasion resistance, mechanical strength and resistance to ultraviolet and nuclear radiation. PVDF is also resistant to fungal growth.

Besides being supplied with a unique pH electrode for meat, the HI98163 has the Hanna's unique CAL Check™ feature that alerts the user to potential problems during the calibration process. This is a very important for the food processor since it is likely that the probe will be coated with the solids found in the food product being measured. This coating can easily lead to errors in pH measurement. By comparing previous calibration data to the current calibration, the meter will inform the user, with display prompts, when the probe needs to be cleaned, replaced, or if the pH buffer might be contaminated. After calibration, the overall probe condition is displayed on screen as a percentage from 0 to 100% in increments of 10%. The probe condition is affected by both the offset and slope characteristics of the pH electrode, both of which can be found in the GLP data.

Pressing the “AutoHold” virtual key in measurement mode, the meter will freeze and automatically log a stable reading. An “out of calibration range” warning can be enabled that will alert the user when a reading is not within the bracket of calibrated pH values.

The log-on-demand mode allows the user to record and save up to 200 samples. The logged data, along with the associated GLP data, can then be recalled or transferred to a PC with Hanna’s HI920015 micro USB cable and HI92000 software for traceability in record keeping for specific product batches. GLP data includes date, time, calibration buffers, offset, and slope, and is directly accessible by pressing the dedicated GLP key.

A contextual help menu based on the screen that is currently being viewed can be accessed at any time by the press of a dedicated button.

The high contrast, graphic LCD screen is easy to view outdoors in bright sunlight as well as in low-lit areas with the backlight. A combination of dedicated and virtual keys allows for easy, intuitive meter operation in a choice of languages.

The compact, durable HI720161 carrying case is thermoformed to hold all necessary components for taking a field measurement, including the meter and electrode, beakers, buffer solutions and cleaning solutions.

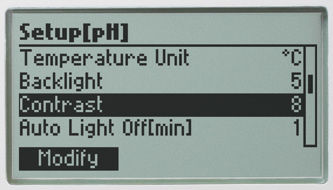

Setup screen

Our extensive setup screen features a host of configurable options such as time, date, temperature units and language for help screens and guides.

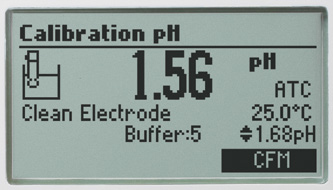

Calibration

pH calibration features detailed CAL Check™ messages. Users are guided through the calibration procedure with step-by-step on-screen instructions.

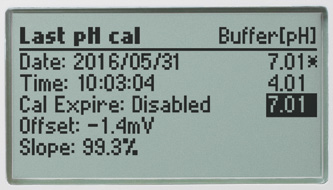

GLP

Comprehensive GLP functions are directly accessible by pressing the GLP key. Calibration data, including: date, time, offset, slope and buffers used in the last calibration can be reviewed.

Features/Benefits:

Ergonomic, rugged, waterproof (IP67) design

Supplied with FC2323 Foodcare pH/Temperature electrode

- Body made of food grade PVDF plastic

- Piercing stainless steel blade for easy penetration into meats

- Open junction design that resist clogging from food solids

- Low temperature pH sensing glass suitable for refrigerated products

- Built in temperature sensor for temperature compensated measurements

Five-point pH calibration with seven standard buffers and five custom buffers CAL Check

- Alerts user to potential problems during calibration including when to clean electrode and possible buffer contamination

- Displays overall condition of the pH electrode after calibration that is based on the offset and slope characteristics

Log-on-demand

- Store measurement data at the press of a button

AutoHold

- Freezes displayed measurement reading upon stabilization

GLP Features

- GLP data including date, time, pH calibration buffers, offset, and slope

- GLP data stored with logged data for traceability

Calibration timeout to alert the user at a defined interval when the calibration has expired

Multiple language selection

200 hour battery life with battery level displayed on measurement screen

Menu driven for ease of use with virtual-key extended functionality

Contextual help at the press of a button

Backlit, graphic LCD

Connectivity

- PC connectivity via a sealed opto-isolated micro USB and HI92000 software

Specifications

| Specification Name | Detail |

|---|---|

| sku | HI98163 |

| pH Range | -2.0 to 20.0 pH / -2.00 to 20.00 pH / -2.000 to 20.000 pH |

| pH Resolution | 0.1 pH / 0.01 pH / 0.001 pH |

| pH Accuracy (@25°C/77°F) | ±0.1 pH / ±0.01 pH / ±0.002 pH |

| pH Calibration | Up to five point calibration, seven standard buffers available (pH 1.68, 4.01, 6.86, 7.01, 9.18, 10.01, 12.45), and five custom buffers |

| mV Range | ±2000.0 mV |

| mV Resolution | 0.1 mV |

| mV Accuracy | ±0.2 mV |

| Temperature Range | -20.0 to 120.0 °C (-4.0 to 248.0 °F) |

| Temperature Resolution | 0.1 °C (0.1 °F) |

| Temperature Accuracy (@25°C/77°F) | ±0.4 °C (±0.8 °F) (excluding probe error) |

| Temperature Compensation | Automatic |

| Log Feature | On demand, 200 samples (100 pH and 100 mV) |

| Connectivity | PC Connectivity opto-isolated USB |

| GLP | Yes |

| Power Supply | 1.5V AA batteries (4 pcs.) |

| Power Consumption | approx. 200 hours of continuous use without backlight (50 hours with backlight) |

| Environment | 3 to 50 °C (32 to 122 °F) max. RH 100% IP67 |

| Dimensions | 188 x 93 x 35.2 mm (7.3 x 3.6 x 1.4”) |

| Weight | 403 g (14.2 oz) |

| Ordering Information | HI98163 is supplied with FC2323 PVDF body pH electrode, HI7004M pH 4.01 buffer solution (230 mL), HI7007M pH 7.01 buffer solution (230 mL), HI700630 electrode acid cleaning solution for meat grease and fat deposits sachet (2), 100 mL plastic beaker (2), 1.5V AA batteries (4), HI92000 PC software, HI920015 micro USB cable, instruction manual with quick start guide, instrument quality certificate and HI720161 hard carrying case. |

| Recommended Probe | FC2323 Foodcare PVDF body, pH electrode with internal temperature sensor, quick connect DIN connector and 1 m (3.3’ cable) |

| Fast Shipping | No |

|---|