Portable Turbidity Meter and Bentonite Monitoring - HI83749

The HI83749 Portable Turbidity and Bentonite Check Meter ensures protein stability before bottling for great quality wine. The HI83749 measures turbidity of samples from 0.00 to 1200 NTU (Nephelometric Turbidity Units) and is USEPA compliant.

- Log and transfer up to 200 measurements.

- GLP (Good Laboratory Practice) feature for traceability of the calibration conditions.

- Great for small & medium wineries and advanced hobbyists.

The HI83749 Portable Turbidity and Bentocheck Meter is specially designed for measurement of turbidity in wine. The instrument is based on a state-of-the-art optical system which guarantees accurate results, assures long term stability, and minimizes stray light and color interferences. It also compensates for variations in intensity of the lamp, although proper calibration ensures measurements are fully validated, comparable, and in compliance with regulatory requirements. The 25 mm round cuvettes composed of special optical glass guarantee the repeatability of turbidity measurements.

Features at-a-glance

AMCO AEPA-1 Primary Turbidity Standard - The AMCO AEPA-1 supplied standards are recognized as a primary standard by the USEPA. These non-toxic standards are made of styrene divinylbenzene polymer spheres that are uniform in size and density. The standards are reusable and stable with a long shelf life.

Calibration – A two, three, or four-point turbidity calibration can be performed by using the supplied (<0.1, 10, 100, and 500 NTU) standards. Calibration points can be modified if user-prepared standards are used.

Fast Tracker™ - For users taking measurements throughout the winemaking process, the HI83749 is equipped with Fast Tracker™ - Tag Identification System (T.I.S.) that makes data collecting and management simpler than ever. Fast Tracker™ allows winemakers to record the time and location of a specific measurement or series of measurements using iButton™ tags on specific tanks for quick and easy readings. Each iButton® tag contains a computer chip with a unique identication code encased in stainless steel.

GLP Data – The HI83749 features complete GLP (Good Laboratory Practice) functions that allow traceability of the calibration conditions. Data includes calibration points, date, and time.

Data Logging – Up to 200 measurements can be stored in the internal memory and recalled at any time.

Data Transfer – For further storage or analysis options, logged data can be downloaded to a Windows compatible PC using the RS232 or USB port and the HI92000 software.

Backlit Display – A backlit LCD display provides an easy to understand, user-friendly interface. Displayed codes guide the user step-by-step through routine operation and calibration.

Significance of Use

Unrefined wine is quite turbid and hazy from suspended solids produced during fermentation. The unrefined wine is treated with fining agents to reduce cloudiness. This cloudiness is what winemakers refer to as protein haze, or haze for short. Thaumatin-like proteins (TLPs) and chitinases are the primary grape proteins responsible for haze formation. These positively charged proteins degenerate and stick together, resulting in undesirable flocculent clouds and visible haziness.

The prevention of protein haze or deposit in bottled white wines is a universal concern and often a wine needs to be stabilized before bottling. One commonly used stabilization agent is bentonite. Bentonite is a volcanic clay earth type fining agent (like kaolin) that acts as a wine stabilizer. It improves the clarity of wine but has also negative aspects because of the volume of lees formed, reduction of tannin and color. Since there are different types and qualities of bentonite with different capacity of protein removal, it is important to make laboratory trials with the same lot and wetting degree of the bentonite as that will be used in the cellar.

Protein stabilization is normally not a problem in bottled red wines because of the relatively high concentration of phenols that binds and precipitates with the unstable proteins before bottling. Often bentonite is added to red wines at a level of about 12 g/hL (1 lb/1000 gal), reducing colloidal suspended particles thus improving membrane filterability.

Wines with low phenols contents, such as rose, light reds and whites should be checked for protein stability before bottling. Hanna offers a rapid test to verify the risk of future protein haze formation. If protein instability is detected, a next test can help defining the right amount of bentonite to be added for improving protein stability. It is important not to overdose bentonite, avoiding stripping wine flavour, body, and significant loss of color, especially in young red wines. Moreover, adding only the necessary amount of bentonite to obtain the desired protein stability results in a reduction of costs.

Winemakers can determine the initial turbidity of the unrefined wine with the HI83749 turbidity measurement instrument. After taking a turbidity reading the pre-made HI83749-20 Bentocheck Solution is added to the wine sample. A second turbidity measurement is taken. If the second turbidity reading is less than the initial turbidity reading plus 2 NTU, the wine can be considered stable. Otherwise a fining trial can be performed to determine the amount of bentonite that must be added to stabilize the wine.

Principal of Operation

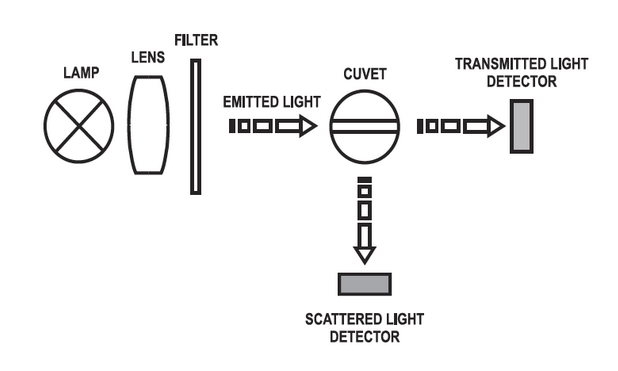

To measure turbidity the HI83749 passes a light beam through the sample that is scattered in all directions. The intensity and pattern of the scattered light is affected by many variables, such as wavelength of the incident light, particle size and shape, refractive index, and color. The optical system of the HI83749 includes a tungsten filament lamp, a scattered light detector (90°) and a transmitted light detector (180°).

The HI83749 features a powerful microprocessor that calculates the NTU value from the signals that reach the two detectors. An effective algorithm is used to correct and compensate for any color interferences. The optical system and measuring technique also compensate for fluctuations in lamp intensity, minimizing the need for frequent calibration.

The HI83749-11 AMCO AEPA-1 standards ensure that measurements are traceable to primary reference materials. These standards are used for calibration and performance verification of the turbidity meter.

Supplied with Certificate of Analysis

- Lot number

- Expiration date

- Standard value @ 25 °C

- Reference meter NIST traceable

Provided storage containers

- Light tight

- Protects from accidental breakage

Specifications

|

sku |

HI83749-01 |

|

NTU Range |

0.00 to 9.99 NTU |

|

NTU Resolution |

0.01 NTU from 0.00 to 9.99 NTU |

|

NTU Accuracy |

±2% of reading plus 0.05 NTU |

|

Range Selection |

Automatic |

|

Turbidity Repeatability |

±1% of reading or 0.02 NTU, whichever is greater |

|

Stray Light |

< 0.05 NTU |

|

Turbidity Light Detector |

Silicon Photocell |

|

Turbidity Method |

Ratio Nephelometric Method. |

|

Calibration |

Two, three or four points calibration |

|

Light Source |

Tungsten filament lamp |

|

Display |

60 x 90mm backlit LCD |

|

LOG Memory |

200 records |

|

Serial Interface |

RS232 or USB 1.1 |

|

Environment |

0 to 50°C (32 to 122°F); max 95% RH non-condensing |

|

Power Supply |

4 x 1.5V AA alkaline batteries or AC adapter |

|

Auto Shut-Off |

After 15 minutes of non-use |

|

Dimensions |

224 x 87 x 77 mm (8.8 x 3.4 x 3.0”) |

|

Weight |

512 g (18 oz.) |

|

Warranty |

2 years |

| Fast Shipping | No |

|---|